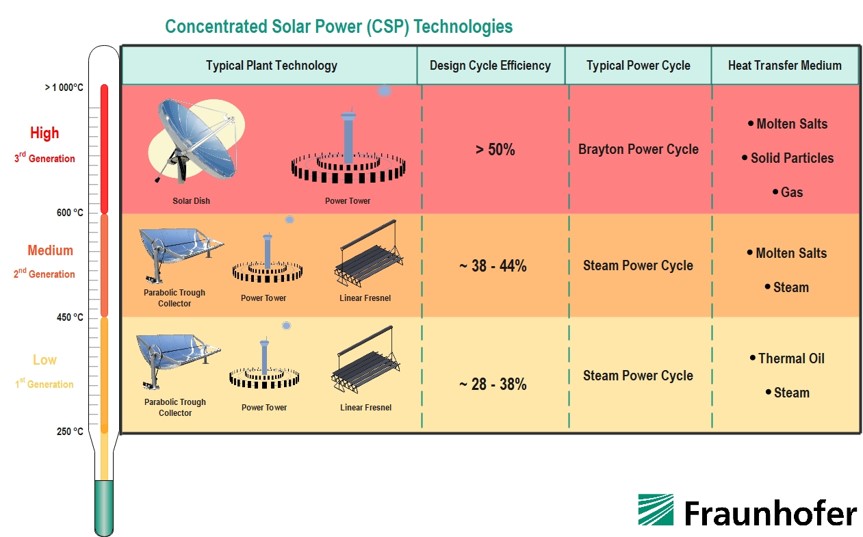

Currently, CSP plants with molten salt storage operate up to temperatures of 565°C, which is limited by the physical properties of molten nitrate salts (2nd gen). Large-scale operation of CSP at higher temperatures (>700°C) remains a challenge to overcome (3rd gen).

With current solar receiver designs (external tubular or cavity gas, air volumetric, solid particle) temperatures above 700°C can be achieved. However, heat transfer media applicable at these temperatures (such as salts, solid particles or gases) must be tested. Cycle efficiency can be expected to increase above 50%, predominantly using the Brayton cycle (such as supercritical CO2) and including storage systems (phase change or thermochemical materials).

The potential of the 3rd CSP is promising, but open challenges need to be captured, studied and solved.

Fraunhofer Chile Research

Fraunhofer Chile Research